The range tends to differ according to the order’s difficulty and volume, but the general rule is that we get the work done within 5-10 working days.

You can request a quote for different types of parts that are made from metal and plastic through Gree-Ge’s CNC Machining Service. Quality prototypes and production parts are delivered in days, free standard shipping included. Our manufacturing network is internationally certified with ISO 9001:2015, ISO 14001, IATF 16949:2016, and ISO 13485, ensuring compliance to high industry standards.

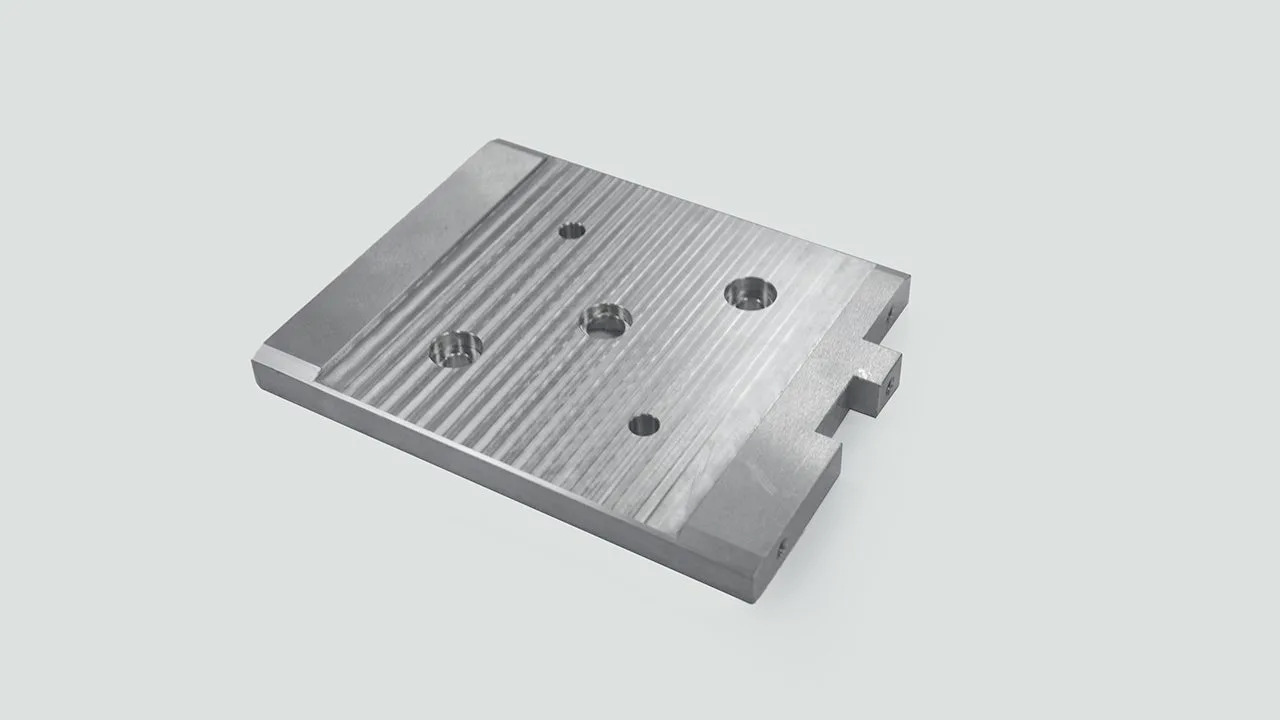

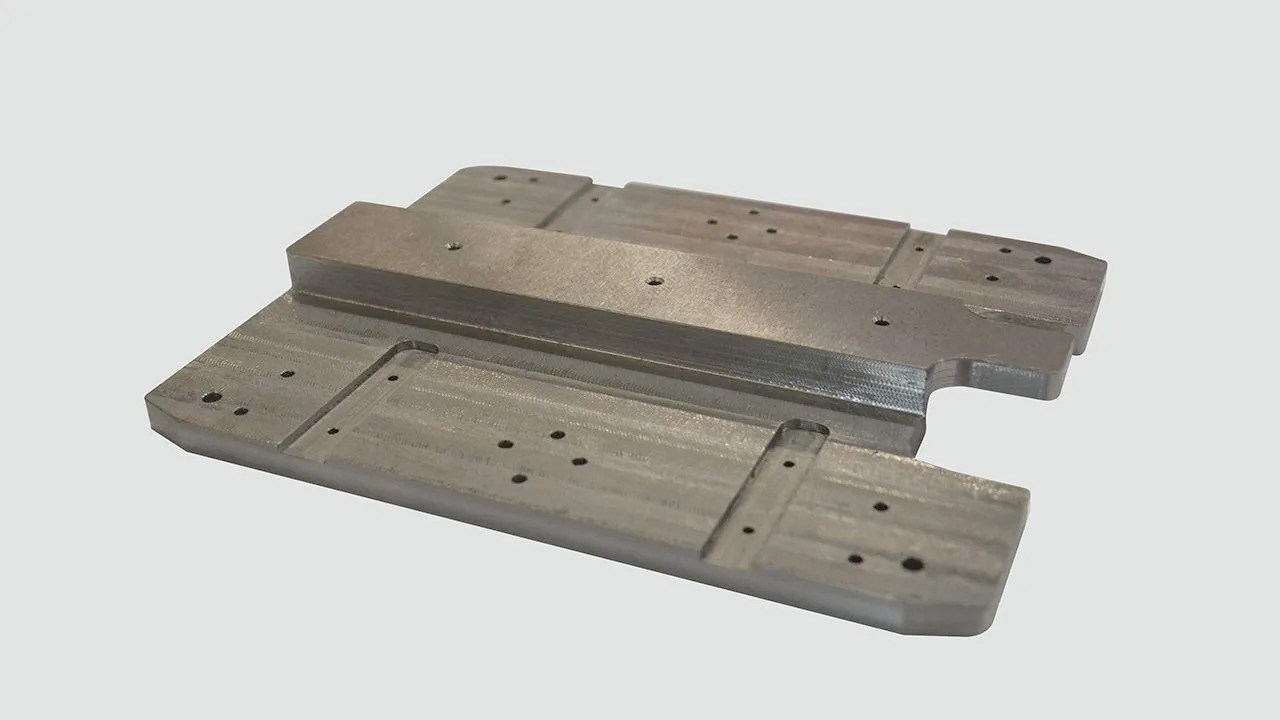

Gree-Ge has a CNC machining service suitable for engineers, designers, and product developers. Due to our vast manufacturing network, we can undertake any project, ranging from rapid prototyping to mass production, regardless of its complexity. Simply upload your CAD file. We’ll will provide you with a competitive price within seconds.

We support over 40 materials such as aluminum, titanium, acetal, PEEK, and Teflon, giving us flexibility across industries.

So let’s get started! With the CAD you have, upload it now and get an instant quote while allowing us to bring your design into the three dimensional world.

CNC stands for Computer Numerical Control and is an automated manufacturing process that utilizes high speed cutting tools to shape plastic and metal materials. Different types of CNC machines such as 3-axis, 4-axis, and 5-axis mills, lathes, and routers can perform the process with high efficiency.

CNC uses CAD models to program the tool paths, guaranteeing accurate production throughout numerous components. Due to this flexibility, custom CNC machined parts have found usage in aerospace, medical, robotics, electronics, and industrial manufacturing.

Comprehensive CNC machining services with advanced technology, high precision, and expertise. Gree-Ge offering high-quality, custom CNC parts with fast turnaround and competitive pricing. Contact us for exceptional results!

Our turning capabilities also include Swiss Machining, perfect for producing intricate, small-diameter parts with tight tolerances, making it essential for round or tubular items.

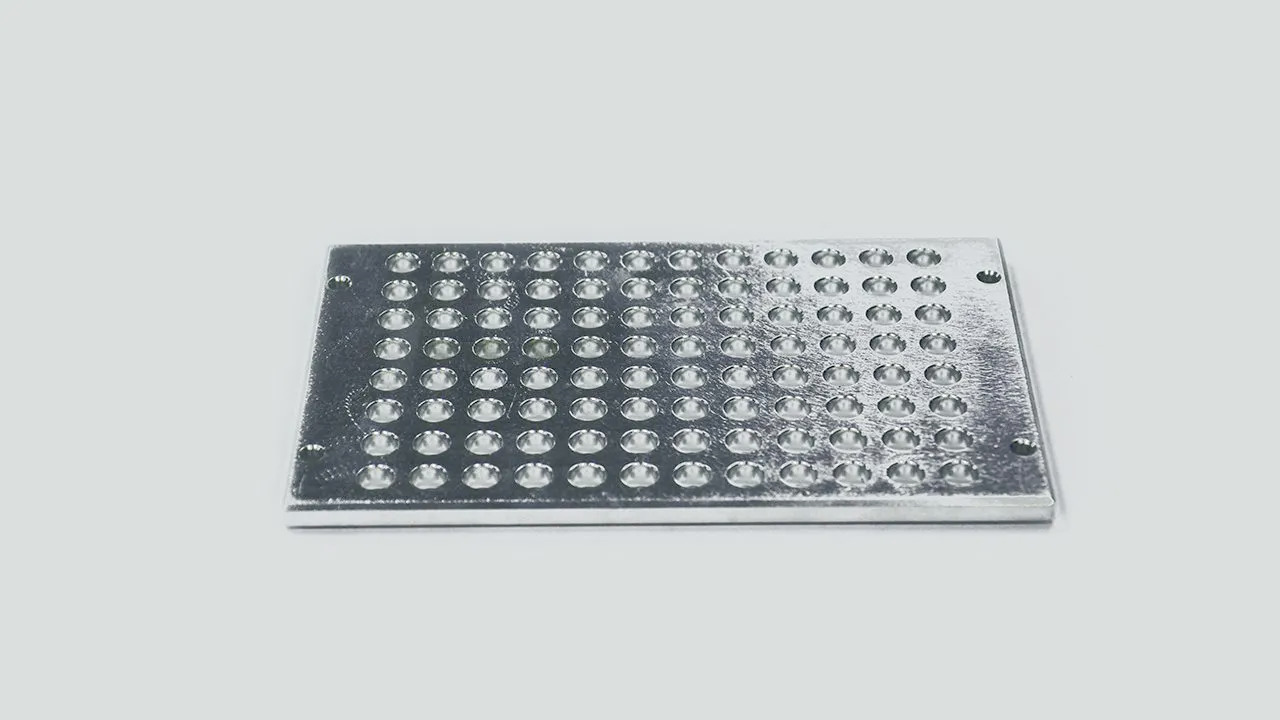

CNC milling process ideal for complex geometries, flat surfaces, and detailed features. The workpiece remains fixed while the multi-axis cutter moves, making it suitable for various materials and intricate designs.

Wire EDM (Electrical Discharge Machining) uses a thin wire as an electrode to cut conductive materials with high precision through electrical discharges. It is ideal for intricate shapes, tight tolerances, and hard materials.

Comprehensive CNC machining services with advanced technology, high precision, and expertise. Gree-Ge offering high-quality, custom CNC parts with fast turnaround and competitive pricing. Contact us for exceptional results!

Our turning capabilities also include Swiss Machining, perfect for producing intricate, small-diameter parts with tight tolerances, making it essential for round or tubular items.

CNC milling process ideal for complex geometries, flat surfaces, and detailed features. The workpiece remains fixed while the multi-axis cutter moves, making it suitable for various materials and intricate designs.

Wire EDM (Electrical Discharge Machining) uses a thin wire as an electrode to cut conductive materials with high precision through electrical discharges. It is ideal for intricate shapes, tight tolerances, and hard materials.

CNC Machining Tolerances ensure precision in manufacturing, allowing for tight tolerances up to ±0.01mm. Achieve high accuracy in custom parts with advanced machining techniques for consistent, reliable, and high-quality results.

| Feature | Description |

|---|---|

| Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter. |

| Standard Lead Time | 3 business days |

| General Tolerances | Tolerances on metals will be held to +/- 0.005" (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”. |

| Precision Tolerances | Gree-Ge can manufacture and inspect to tight tolerances, including sub +/- 0.001" tolerances, per your drawing specifications and GD&T callouts. |

| Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

| Threads and Tapped Holes | Gree-Ge can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

| Edge Condition | Sharp edges are broken and deburred by default |

| Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

| Aluminium Alloy | Description | Finishing Options | Applications |

|---|---|---|---|

| 6061 | Versatile and commonly used for structural applications. | Anodizing, Powder Coating, Polishing | Construction, Aerospace, Automotive |

| 7075 | High strength, ideal for aerospace and military applications. | Anodizing, Powder Coating, Polishing | Aerospace, Military, High-Strength Components |

| 2024 | Known for its high strength and excellent fatigue resistance. | Anodizing, Cladding, Painting | Aerospace, Military, Structural Components |

| 5052 | Good corrosion resistance and formability, used in marine and automotive applications. | Anodizing, Painting, Polishing | Marine, Automotive, Sheet Metal Work |

| 5083 | Exceptional performance in extreme environments, particularly marine applications. | Anodizing, Painting, Polishing | Marine, Chemical, Industrial |

| 6082 | Excellent extrudability, used for architectural and engineering applications. | Anodizing, Powder Coating, Polishing | Architecture, Engineering, Window Frames |

| 7050 | High strength and stress corrosion resistance, often used in aerospace. | Anodizing, Cladding, Painting | Aerospace, High-Stress Components |

| 1100 | Commercially pure aluminum, excellent corrosion resistance and workability. | Anodizing, Painting, Polishing | Chemical Equipment, Food Processing, Heat Exchangers |

| Brass Alloy | Description | Finishing Options | Applications |

|---|---|---|---|

| C260 | Cartridge brass, excellent for cold working. | Plating, Polishing, Lacquering | Ammunition, Heat Exchangers, Plumbing |

| C360 | Free machining brass, used for precision parts. | Plating, Polishing, Lacquering | Precision Machined Parts, Fasteners, Plumbing |

| C353 | High leaded brass, high strength, used in plumbing. | Plating, Polishing, Lacquering | Plumbing, Fasteners, Valve Components |

| C385 | Architectural bronze, applications for its decorative appeal. | Plating, Polishing, Lacquering | Architectural Trim, Ornamental Hardware, Plumbing |

| C272 | Yellow brass, excellent corrosion resistance, used in electrical components. | Plating, Polishing, Lacquering | Electrical Components, Fasteners, Plumbing |

| Copper Alloy | Description | Finishing Options | Applications |

|---|---|---|---|

| C101 | Oxygen-free, high conductivity, used in electrical applications. | Plating, Polishing, Lacquering | Electrical Conductors, Switches, Terminals |

| C110 | Electrolytic tough pitch, highly conductive, used in electrical and plumbing. | Plating, Polishing, Lacquering | Electrical Wiring, Plumbing, Busbars |

| C122 | Phosphorus-deoxidized, used in heat exchangers and radiators. | Plating, Polishing, Lacquering | Heat Exchangers, Radiators, Plumbing |

| C172 | Beryllium copper, high strength, used in aerospace and oil drilling. | Plating, Polishing, Lacquering | Aerospace, Oil Drilling, Springs |

| C194 | High conductivity, used in automotive and electrical applications. | Plating, Polishing, Lacquering | Automotive Connectors, Electrical Connectors, Springs |

| C210 | Low brass, good ductility and strength, used in fasteners and hardware. | Plating, Polishing, Lacquering | Fasteners, Hardware, Musical Instruments |

| C220 | Commercial bronze, used in jewelry and musical instruments. | Plating, Polishing, Lacquering | Jewelry, Musical Instruments, Architectural Hardware |

| C230 | Red brass, used in architectural applications and hardware. | Plating, Polishing, Lacquering | Architectural Applications, Hardware, Plumbing |

| Grade | Description | Finishing Options | Applications |

|---|---|---|---|

| 301 | Excellent machinability, used for making automotive parts bolts, nuts, and screws. | Polishing, Passivation, Bead blasting | Used for making automotive parts, bolts, nuts, and screws. |

| 304 | Most versatile and widely used stainless steel, used in kitchen equipment tanks, piping, and tubing. | Polishing, Brushing, Passivation | Used in kitchen equipment, tanks, piping, and tubing. |

| 304L | Low carbon version of 304, used for chemical containers and transport. | Electropolishing, Passivation, Bead blasting | Used for chemical containers and transport. |

| 316 | Contains molybdenum for increased corrosion resistance, used in marine applications and chemical processing equipment. | Polishing, Passivation, Bead blasting | Used in marine applications and chemical processing equipment. |

| 316L | Low carbon version of 316, used for surgical instruments and marine hardware. | Electropolishing, Passivation, Bead blasting | Used for surgical instruments and marine hardware. |

| 410 | Martensitic grade, used for fasteners and medical instruments. | Hardening, Polishing, Passivation | Used for fasteners and medical instruments. |

| 416 | High machinability, used for gears, shafts, and valves. | Polishing, Passivation, Bead blasting | Used for gears, shafts, and valves. |

| 420 | High hardness, used for surgical instruments and cutlery. | Hardening, Polishing, Passivation | Used for surgical instruments and cutlery. |

| 430 | Ferritic grade, used for automotive trim and dishwashers. | Polishing, Brushing, Passivation | Used for automotive trim and dishwashers. |

| Steel Alloy | Description | Finishing Options | Applications |

|---|---|---|---|

| 4140 | Chromium-molybdenum steel with high toughness and good fatigue strength. | Heat Treating, Anodizing, Powder Coating | Gears, Shafts, High-Stress Components |

| 4340 | Nickel-chromium-molybdenum steel with excellent toughness and strength. | Heat Treating, Anodizing, Powder Coating | Aircraft Landing Gear, Automotive Parts, Heavy Duty Shafts |

| 8620 | Nickel-chromium-molybdenum alloy steel, case hardening steel. | Carburizing, Heat Treating, Plating | Gears, Pins, Automotive Parts |

| 1018 | Low carbon steel, good weldability and machinability. | Painting, Powder Coating, Galvanizing | Structural Applications, Shafts, Spindles |

| 1045 | Medium carbon steel, high strength and impact resistance. | Heat Treating, Plating, Painting | Gears, Shafts, Machinery Parts |

| 4130 | Chromium-molybdenum alloy steel, good strength and toughness. | Heat Treating, Anodizing, Powder Coating | Aircraft Components, Bicycle Frames, Automotive Parts |

| 1210 | Low carbon steel, good formability and weldability. | Galvanizing, Painting, Powder Coating | Automotive Parts, Machinery Components, Structural Steel |

| 17-4 PH | Precipitation-hardening stainless steel, high strength and hardness. | Heat Treating, Anodizing, Passivation | Aerospace Components, High-Strength Applications |

| Titanium Alloy | Description | Finishing Options | Applications |

|---|---|---|---|

| Grade 1 | Commercially pure titanium, excellent corrosion resistance and formability. | Anodizing, Polishing, Sandblasting | Chemical Processing, Marine, Medical |

| Grade 2 | Commercially pure titanium, balance of strength and ductility. | Anodizing, Polishing, Sandblasting | Aerospace, Medical, Marine |

| Grade 5 (Ti-6Al-4V) | Most commonly used titanium alloy, high strength and light weight. | Anodizing, Polishing, Heat Treating | Aerospace, Medical Implants, Marine |

| Grade 9 | Titanium alloy with good weldability and cold formability. | Anodizing, Polishing, Sandblasting | Aerospace, Chemical Processing, Marine |

| Grade 23 (Ti-6Al-4V ELI) | Extra-low interstitial variant of Grade 5, high strength and toughness. | Anodizing, Polishing, Heat Treating | Medical Implants, Aerospace, Marine |

| Grade 7 | Commercially pure titanium with excellent corrosion resistance. | Anodizing, Polishing, Sandblasting | Chemical Processing, Marine, Medical |

| Grade 12 | Titanium alloy with excellent corrosion resistance and strength. | Anodizing, Polishing, Heat Treating | Chemical Processing, Marine, Aerospace |

| Plastic Material | Description | Finishing Options | Applications |

|---|---|---|---|

| ABS | Acrylonitrile Butadiene Styrene, good impact resistance and toughness. | Painting, Plating, Sanding | Automotive Parts, Consumer Products, Enclosures |

| PC | Polycarbonate, high impact resistance and transparency. | Polishing, Sandblasting, Painting | Optical Discs, Safety Equipment, Automotive Parts |

| PMMA | Polymethyl Methacrylate (Acrylic), excellent optical clarity and weather resistance. | Polishing, Sanding, Painting | Displays, Lenses, Lighting Fixtures |

| POM | Polyoxymethylene (Delrin/Acetal), high stiffness and low friction. | Machining, Sanding, Polishing | Gears, Bearings, Medical Devices |

| PEEK | Polyetheretherketone, high temperature and chemical resistance. | Machining, Sanding, Polishing | Aerospace, Medical Implants, Semiconductor Parts |

| PP | Polyphenylene , high mechanical and thermal properties. | Machining, Sanding, Polishing | Automotive, Electrical Components, Industrial Applications |

| PA66 | Polyamide (Nylon 66), high mechanical strength and rigidity. | Machining, Sanding, Polishing | Mechanical Parts, Automotive, Electrical Insulation |

| PEI | Polyetherimide (Ultem), high strength and excellent electrical properties. | Machining, Sanding, Polishing | Aerospace, Medical Devices, Electrical Components |

| SAN | Styrene Acrylonitrile, good chemical resistance and transparency. | Machining, Sanding, Polishing | Housewares, Cosmetic Containers, Automotive Parts |

| HIPE | High Impact Polystyrene, good impact resistance and machinability. | Machining, Sanding, Painting | Packaging, Consumer Products, Electrical Insulation |

| HIPD | High Impact Polypropylene, high impact resistance and low density. | Machining, Sanding, Painting | Automotive Parts, Industrial Applications, Consumer Goods |

| Fiber-Reinforced Materials | Composite materials with enhanced mechanical properties. | Machining, Sanding, Painting | Aerospace, Automotive, Sporting Goods |

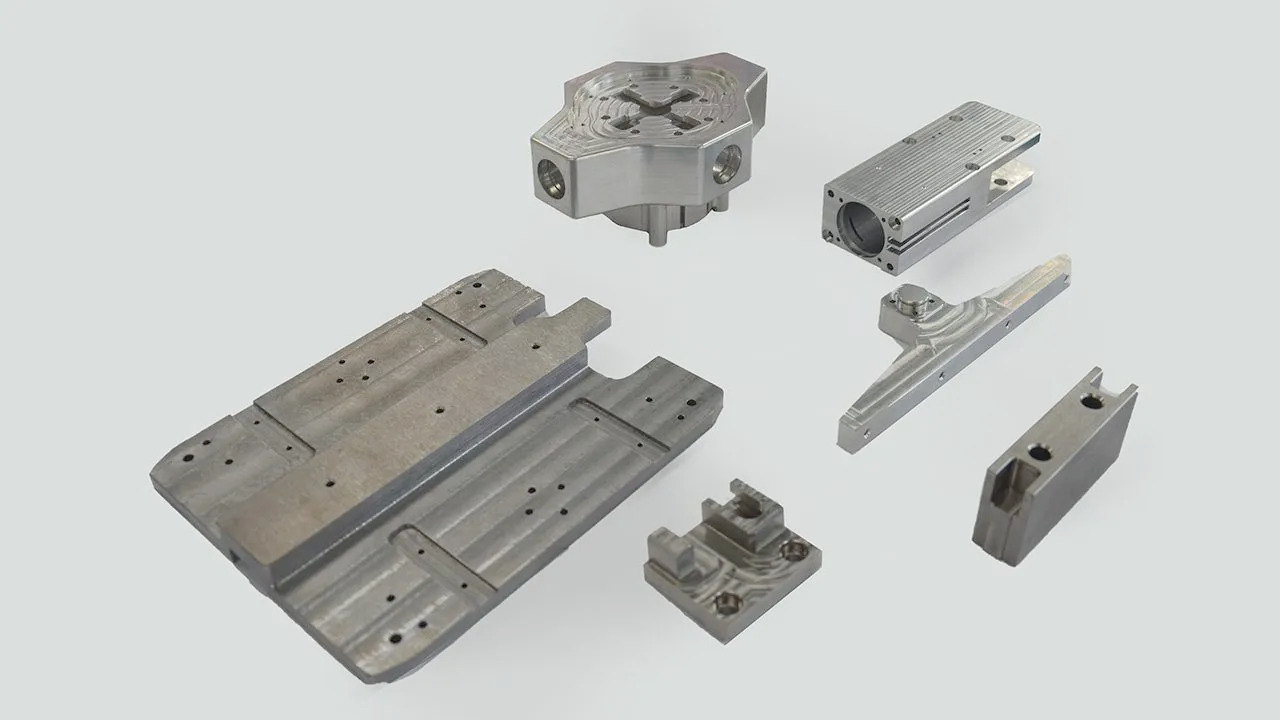

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

CNC (Computer Numerical Control) machining is an advanced technology that has changed the face of industry by automating machine tools for high precision manufacturing. It allows for rapid prototyping and large volume production with a high level of precision, efficiency, and uniformity.

Gree-Ge provides excellent CNC machining services while specializing in engineering parts that require high level competence in machining and supplying them within deadline in different industries.

Precision & Accuracy: CNC machines can work with tolerances of up to ±0.005 mm for each component.

Efficiency & Speed: Due to automation, production time, personnel costs and output all increase.

Versatility Can process many materials: metals, plastics, and composites.

Scalability: Suitable for prototypes and other designed elements as well as for volume production.

Less Waste: Optimal cutting paths waste minimal materials, therefore offering efficiency in cost per minute spent on CNC machining.

We guarantee to meet all your CNC machining needs at Gree-Ge:

With CNC milling, materials are cut off from the workpiece using rotary cutting tools. It is best for cutting complex shapes and accurately placed slots or holes. Our state-of-the-art multi axis milling machines can easily accomplish high complexity parts.

In CNC turning, the workpiece is moved, and the cutting tool shapes the workpiece to desired specifications. It is used for making cylindrical or symmetrical items most often shafts, bushings, and threaded parts.

Multi-Axis Machining

We are experts in CNC machine programming for 3 axis, 4 axis, and 5 axis CNC machines, which can perform the difficult tasks of multi-part setups in a single position. Multi-axis machining ensures ease of machining and better productivity owing to the increase in accuracy and reduction in set up time.

Gree-Ge offers custom prototyping services to help clients bring a product idea to market much faster. Clients work with us to mold the design into a working prototype to ensure performance standards are met prior to large scale production.

We handle different materials like aluminum, stainless steel, titanium, brass, and copper, and also ABS, nylon, PEEK and polycarbonate. The selection of the materials is made according to the application and performance expectations of the specific project.

CNC Micromachining is practiced in many fields, and Gree-Ge has experience producing and supplying good quality products in these fields:

Gree-Ge has earned a reputation as a reliable provider of CNC machining services because of our focus on quality, speed, and customer satisfaction. Among others, these are the reasons why clients choose us:

Gree-Ge has been able to provide superior CNC machining services customized for your needs. From rapid prototyping, bespoke parts fabrication, and large volume procurement, we are experienced enough to deliver unmatched results.

Reach out to us now and get started on your CNC machining project!

What is the typical lead time for CNC machining?

The range tends to differ according to the order’s difficulty and volume, but the general rule is that we get the work done within 5-10 working days.

What materials can Gree-Ge CNC machine?

We can use aluminum, steel, titanium, and brass as well as plastics like ABS, PEEK, nylon, and polycarbonate for different applications.

Can you handle small-batch production?

We certainly do. We ensure punctuality and minimal wastage for both prototypes and orders requiring low volume production.

Do you offer design support?

Yes, Gree-Ge engineers will assist you with DFM (Design for Manufacturability) so your designs are easier to do with CNC machining.

Is CNC machining suitable for complex geometries?

Our capacity to perform machining on five-axis, makes it possible for us to produce parts that are very complex in shape with great accuracy.